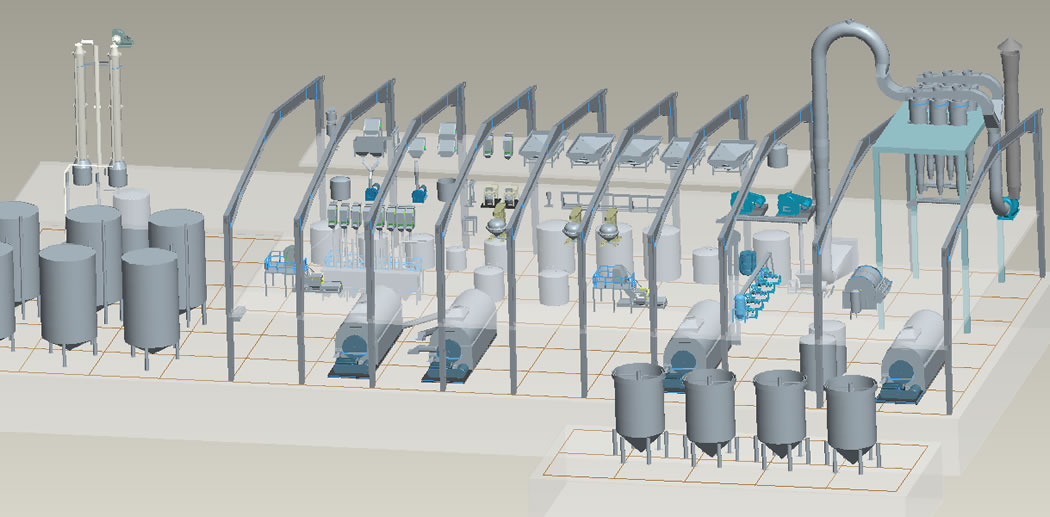

Maize starch plant machinery

Ⅰ. Maize starch introduction

Maize starch is a product made from corn kernels, which is made by immersing maize kernels with sulfurous acid, crushing, screening, separating, washing, dehydrating and drying. This product is mainly used in the pharmaceutical, food,

chemical, textile and other industries. In recent years, with the development of production in various industries, maize starch has been widely used because of its wide application, excellent performance and moderate price. In addition

to the main products of maize starch, the maize starch plant machinery described in this article can also obtain three by-products of maize oil, protein powder and maize slurry.

Ⅱ. Maize starch plant machinery and process description:

Loading

Purpose: To receive the maize sent from the maize pre-purification section, after de-ironing, dust removal and sand removal, to provide purified maize for the soaking process.

Used maize starch plant machinery: scraper conveyor, induced draft fan, cascade magnet, cyclone separator, hopper, rotary valve, weighing scale, maize conveying water tank, maize loading pump, maize conveying water pump, maize conveying

water heat exchanger, soaking ground pit recovery pump.

Acid production

Purpose: To prepare a certain concentration of sulfurous acid solution. The sulfurous acid preparation process is mainly composed of maize starch plant machinery of an absorption tower, an induced draft fan, a combustion furnace and the like.

Sulfurous acid production flow chart: sulfur furnace → absorption tower → sulfuric acid intermediate tank → steam separator → sulfuric acid storage tank

Used maize starch plant machinery: sulfur dioxide absorption tower, sulfur burning furnace, sulfuric acid preparation tank, sulfuric acid intermediate tank, sulfurous acid transfer pump, exhaust gas fan, sulfurous acid storage tank,

plate heat exchanger, dilute corn gluten water pump

Soaking

Objective: To soften maize granules and reduce the mechanical firmness of maize granules while leaching some soluble substances such as inorganic salts, water-soluble proteins and sugars. The fibers, germs, and proteins are more easily

separated from the starch.

Main maize starch plant machinery: soaking tank, soaking liquid circulation pump, plate heat exchanger, sulphurous acid heat exchanger, wet maize transfer pump, sulfurous acid storage tank, sulfurous acid transfer pump, thin maize slurry

storage tank, soaking system exhaust fan

Evaporation

Purpose: In order to recover the valuable components in the dilute soaking liquid discharged from the immersion system, it is sent to this process for evaporation and concentration to produce concentrated maize slurry.

Equipped maize starch plant machinery: dilute soaking liquid storage tank, dilute soaking liquid transfer pump, dilute soaking liquid evaporation system, evaporator, circulation pump, hot well pump, concentrated maize slurry pump ,

separator, surface condenser, steam heater (preheater)

Grinding

Purpose: In order to separate the germ, fiber and the subsequent separation of starch and protein, the maize is broken into pieces by maize starch plant machinery, the germ and endosperm are separated, and the starch is as free of fat as

possible.

Grinding flow chart:

maize storage bucket → first stage grinding → first stage germ separator → second grinding liquid tank → second stage germ separator → third stage pre-grinding sieve → third stage grinding →third grinding liquid tank

Maize starch plant machinery used include: wet maize hopper, maize milling machine, agitator, primary germ separation pump, germ separator, second stage pre-milling dewatering screen, second stage grinding machine, grinding Liquid tank,

germ separation pump, fine grinding feed tank, fine grinding feed pump, pre-grinding curved sieve, fine grinding, fine grinding liquid tank, slurry tank, exhaust fan

Fiber washing, dehydration and drying

Objective: The finely ground material is separated and washed by a pressure curved sieve, and the fiber in the material is extracted, dehydrated by an extruder and sent to a fiber drying system.

Flow chart:

Third stage grinding liquid tank → fiber washing tank → fiber slurry tank → fiber screw extruder → fiber slurry dryer

Main maize starch plant machinery: fiber separation curved sieve, fiber separation curved sieve feed pump, fiber washing tank, balanced distribution automatic valve, fiber washing curved sieve, fiber extrusion dewatering machine, fiber

dewatering machine, exhaust fan

Starch slurry sand removal, concentration; starch gluten separation and gluten concentration

Purpose: The main purpose of starch slurry sand removal is to reduce the wear and tear of the maize starch plant machinery and reduce the sand content of the product; the main purpose of preconcentration is to reduce the feed volume of

the main centrifuge and provide process water for the system; the main centrifugal sieve is used for starch and gluten separation; gluten concentrate centrifuge is mainly used to concentrate gluten and provide a certain amount of process

water to the system.

Equipped maize starch plant machinery: slurry tank, slurry pump, pumping pump, slurry desander, rotary filter, preconcentration centrifuge, main centrifuge feed tank, main centrifuge feed pump, agitator, emergency reserve tank, process

water pump, main centrifuge sieve, reflux rotary filter, washing filter, dilute gluten tank, feed pump, rotary filter, gluten concentrate centrifuge, starch milk tank, gluten storage tank, hydraulic pump, process water pump

Protein dehydration

Objective: The protein concentrated by the protein concentration centrifuge is dehydrated by a vacuum filter, and then sent to a screw conveyor to enter the protein drying system.

Flow chart:

Concentration and centrifugation of concentrated gluten → concentrated gluten storage tank → gluten vacuum filtration → gluten filter cake spiral → gluten dryer

Equipped maize starch plant machinery: vacuum drum feeding pump, vacuum pump, filtrate receiving tank, flushing pump, rotary filter, shell-and-tube heat exchanger, vacuum drum filter, filtrate pump, screw conveyor, discharging shaft,

cooling pump , reflux pump, vacuum pump circulating water tank

Protein drying

Purpose: The dehydrated protein passes through a protein tube bundle dryer to achieve a safe moisture.

Flow chart:

Maize gluten vacuum filtration → gluten filter cake spiral → return screw conveyor → wet corn gluten crusher → feed screw conveyor → gluten dryer → discharge screw conveyor → wet gluten milling → powder gluten conveyor fan →

packaging process

Used maize starch plant machinery: protein dryer, exhaust fan, return screw conveyor, bucket elevator, mixing screw conveyor, hammer mill, drum screen, cyclone, rotary valve, conveying fan

Starch Dehydration and Drying

Objective: The starch milk refined by the starch refining process is dehydrated by a peeler centrifuge, then sent to a flash dryer for drying, and the dried starch is transported to maize starch plant machinery for packaging, and then

packaged into a finished starch.

Flow chart:

Refined starch milk storage tank→fine starch milk high level tank→ peeler centrifuge→disintegration metering device→discharge screw→sparger→starch air flash dryer→cyclone separator→rotary valve→dry starch conveying fan→starch

grinding→ packing workshop

Main maize starch plant machinery: fine starch milk pump, agitator, scraper overflow tank, scraper overflow pump,separator, starch airflow dryer, starch milk high tank, peeler centrifuge, scraper filtrate tank, scraper filtrate pump ,

backwash tank, rotary filter

Starch packaging

Objective: To package the starch delivered from the flash dryer into different finished products of different weights according to the requirements of sales and product safety, and check the storage.

Equiped maize starch plant machinery: bag filter, starch storage tank, electronic scale, conveyor, vibrating screen feeding screw, seam machine, dust removal fan, computer control cabinet, vibrating screen, pressure relief fan

The above is the complete set of maize starch plant machinery, any more detail aout the machinery and maize starch production technology, welcome to contact our engineer.