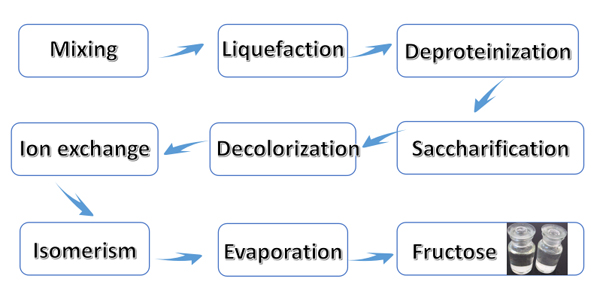

Then next is our glucose fructose syrup production machine divided introduction:

1.Mixing tank:

Mixing the starch and water to get the right density slurry, add certain enzyme, adjust the PH value and temperature to get the starch milk. Now our advanced technology for glucose fructose syrup production also can use the corn/ rice powder as raw material directly.

2. Liquefaction tank & ejector:

Usecd in the liquefaction process can convert the starch into liquid dextrin, the liquefaction tank include the laminar tank, maintaining tank and neutralization tank.

3. Plater frame filter press machine:

On the before introduction, you can know that this machine is used in two sections for the glucose fructose syrup production, not only the deproteinization, but also the decolorization process. It's ann important machine for the syrup purity. The deproteinization process function is separate the protein and other solid impurity from liquid dextrin, with automatic mechanical extrusion method.

On the other side, plate frame filter press used for the decolorization process is adopted the activated carbon adsorption principle, the decolorization & decarbaurization normal sequence is the first decolorization-the first decarburization-The second decolorization-the second decarburization.

4. Saccharification tank:

After liquefaction, the pH value is reduced to between 4.2 and 4.5, after the solution temperature is cooled to 60 ℃, added the glucomylase (Novo’s AMG 300L) immediately. The reaction time for saccharification is usually between 24-48 hour depending on enzyme reaction speed. Glucoamylase releases single glucose units from the ends of dextrin molecule, syrups of 95% glucose or higher are manufactured by the saccharification tank, important for the glucose fructose syrup production.

5. Ion exchange column:

Ion exchange process for glucose fructose syrup production, can remove the Ca2+ and Mg2+ etc, and the negative ions, pure the syrup, the resin need regeneration by acid and alkali washing after working for some days.

6. Isomerism process:

The isomerism system can make the purified glucose solution isomerized by a reactor containing immobilized isomerase to obtain fructose syrup with 42% fructose content. It's honor to tell you that the isomerase we are using is a kind of immobilized enzyme. Converted from soluble state into immobilized state, the stability of isomerism will be increased significantly and it can be uses repeatedly in the high fructose corn syrup produced. This immobilized enzyme used in food processing make food free of enzyme after production, so there is no need to adopt the way of heat treatment to make enzyme inactivated, which can help improving the quality of food as well as economic benefits.

7. Evaporator:

Evaporation process for glucose fructose syrup production is aimed to remove the excess moisture from the syrup liquid. We will suggest you the most suitable type evaporator as your production requests.