list of rice glucose syrup plants in pakistan

Release Time:2020-07-14 18:46Author:sd888Source:未知

Any questions about the product can be communicated with us at any time!

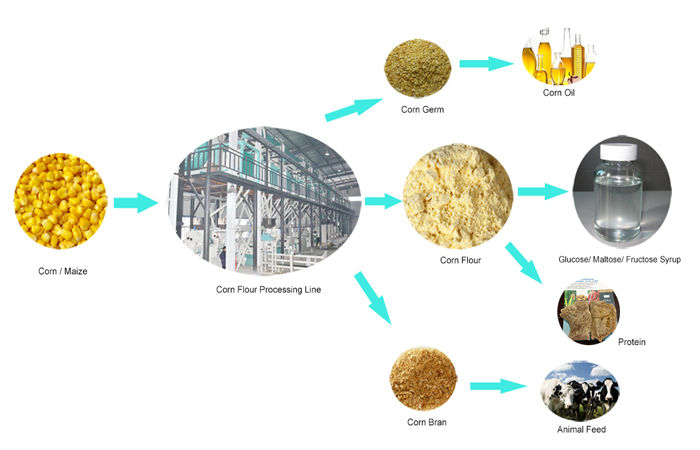

Part A: Corn glucose syrup production line- corn flour making part

Step 1. Corn selection part:

(1). Lifting: Using Bucket elevator to lift corn to next working section.

(2). Screening: To screen and clean corn by vibration principle, and remove impurity

(3). Storage: Stock good corn for next working section in glucose syrup production line.

Step 2. Remove corn germ

(1). Remove corn germ: To broke corn and remove skin, germ.

(2). Selecting germ and packing: To select and pack germ from above section.

(3). Conveying: Delivery broken corn to next section by conveyor.

Step 3. Corn to make corn flour

(1). Broken: to broke corn for milling.

(2). Corn flour production: mill corn to flour by Roller Mill, then send to next step.

Corn glucose syrup production line- corn flour to produce glucose syrup

1.Continuous spray liquefaction section

(1).Mixing slurry: Add thermostable amylase and water to flour, and mix them in mixing slurry tank

(2).Spray liquefaction: Heating all tanks by steam, then start Liquid ejectors and pumps. Delivery material continuously and evenly, and control flow by production capacity.

Flash evaporate material in Laminar flow tank, and keep temperature. Observe liquefaction effect.

(3).High temperature treatment: Send passed material to the second Liquid ejector, and keep temperature.

(4).Carry slurry to buffer tank by pump in glucose syrup production line.

2.Filtration section:

(1).Filter protein and slag by Plate-and-frame filter press machine.

(2).Carry away protein and slag by Bottom slot for plate-and-frame filter press machine.

(3).Syrup inflow buffer tanks, then be sent to next step by pump in glucose syrup production line.

3.Saccharification section in corn glucose syrup production line

Cooling syrup by Heat-exchanger, then send them to Saccharification tank (mixer and coil pipe are set in Saccharification tank. ) by Pumps., then add glucoamylase

4.Decolorization

Carry passed syrup into Decolorization tanks(mixer and coil pipe are set in Saccharification tank.) by pump. Decolor by Activated carbon

5.Filtration section in corn glucose syrup production line

(1).Filter protein and Activated carbon by Plate-and-frame filter press machine.

(2).Carry away protein by Bottom slot for Plate-and-frame filter press machine

(3).Unclean syrup is sent to big buffer tanks by pump.

(4).Carry clean syrup into buffer tanks.

6.Ion exchange section

(1).Carry syrup into Ion exchange columns. Resin clean syrup in Ion exchange columns. Then carry clean syrup into buffer tanks.

(2).When Resin loses effect, stop carry syrup into Ion exchange columns, and change another Ion exchange column in glucose syrup production line for work.

(3).Recover Resin: Using heat water to bush resin, then use acid fluid, and alkali fluid to bush Ion exchange columns till resin has function.

7.Evaporation section in corn glucose syrup production line

Evaporate syrup by triple-concentrate of evaporator and Single-concentrate of evaporator. When syrup concentration is OK, shut down steam and stop evaporation. And carry syrup to Final-product storage tanks by Pumps.

8.Final corn glucose syrup storage