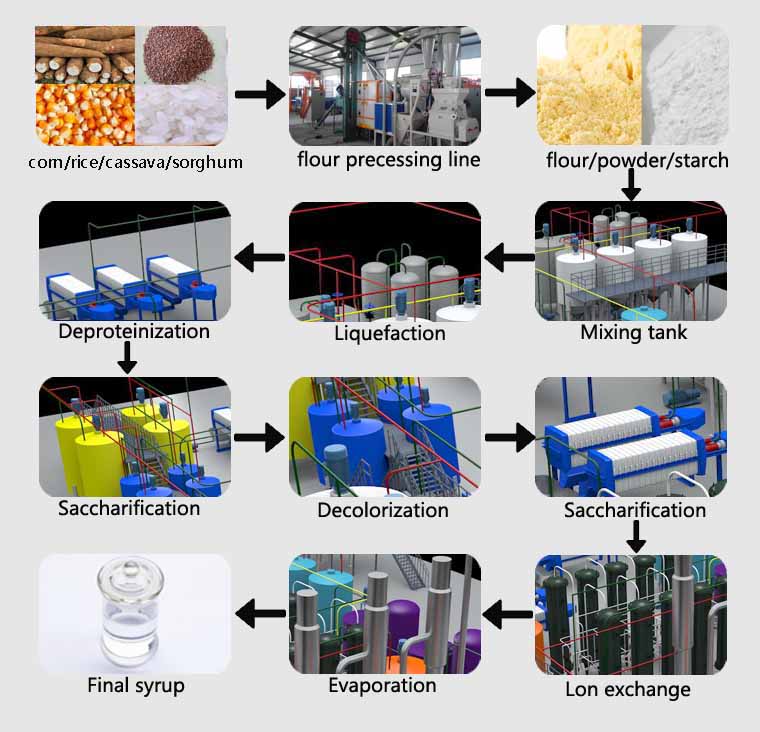

syrup manufacturing production processing machines

Release Time:2020-06-26 17:46Author:sd888Source:未知

Any questions about the product can be communicated with us at any time!

1. Production of sorghum cassava corn rice starch: extract refined sorghum cassava corn rice starch from sorghum cassava corn rice

2 Mixing: adjust the DS value of starch in the sorghum cassava corn rice starch production line to 28-32%, and control the appropriate PH and temperature values. Or add a certain amount of water to achieve the above conditions, and then go to the next section.

3 Liquefaction and heating: The starch milk is sent to the buffer tank, and then it is liquefied by means of enzymes using a jet cooker.

4. Saccharification: The liquefied substance maintains a certain reaction time under the action of enzymes. Will produce the required DE value of sorghum tapioca corn rice syrup.

5. Filtration and decolorization: To produce clarified sorghum cassava corn rice syrup, the sorghum cassava corn rice syrup is decolorized by activated carbon at an appropriate temperature, and finally sent to the filter to remove the activated carbon, and then sent to the next part.

6. Ion exchange: In order to produce high-quality sorghum cassava corn rice syrup, transparent sorghum cassava corn rice syrup will be passed through the ion exchanger to improve the purity of sorghum cassava corn rice syrup.

6. Finished product storage tank: to maintain the purity of glucose syrup and easy transportation.

7. Evaporation: The sorghum cassava corn rice syrup is thoroughly washed through a safety filter, and then sent to the evaporator for concentration to achieve the required DS of the final product.

8. Finished product storage tank: Maintain the purity of sorghum cassava corn rice syrup and convenient transportation.

Our company can provide complete sorghum cassava corn rice starch processing machine and sorghum cassava corn rice syrup processing machine to help customers produce sorghum cassava corn rice syrup directly from sorghum cassava corn rice and get more profit from sorghum cassava corn rice.

Sorghum cassava corn rice syrup, also known as glucose syrup, is a concentrated aqueous solution of glucose, maltose, and other nutrient sugars obtained from sorghum cassava corn rice syrup processing plant edible sorghum cassava corn rice starch. Sorghum cassava corn rice syrup is widely used in fruits, wine, crystalline fruits, baked products, medicines and beer products.

The production process of the sorghum cassava corn rice syrup processing plant is divided into two parts: the first part is to make sorghum cassava corn rice starch with fresh sorghum cassava corn rice starch, the second part is to make sorghum cassava corn with sorghum cassava corn rice starch Rice syrup. This technology can bring economic and social benefits to farmers who produce sorghum, cassava, corn and rice. , Entrepreneurs and end users who produce syrup.

How to produce sorghum cassava corn rice syrup in sorghum cassava corn rice syrup processing plant?

The process details of the sorghum cassava corn rice glucose syrup processing plant are as follows:

1. Sorghum cassava corn rice syrup processing plant produces sorghum cassava corn rice starch

Sorghum cassava corn rice starch production line can automatically produce high-quality sorghum cassava corn rice starch from sorghum cassava corn rice, and then use sorghum cassava corn rice starch to prepare glucose syrup.

2. Starch milk adjustment in sorghum cassava corn rice syrup processing plant

Adjust the starch milk from the starch factory to DS28-32%, and adjust the appropriate pH and temperature. Or mix dry starch with water to achieve the next part of the above conditions.

3. Liquefaction of sorghum cassava corn rice syrup processing plant

The starch milk is sent to the buffer tank, and then liquefied by the spray cooker with the help of enzymes.

4. Saccharification of sorghum cassava corn rice syrup processing plant

The liquefied material is sent to the enzyme saccharification tank for reaction. After remaining in the tube, the required glucose DE value will be reached. The material is then sent to flash cooling and then sent to the neutralization tank to obtain the proper pH value.

5. Filtration and decolorization process of sorghum cassava corn rice syrup processing plant

Glucose is cleaned by removing proteins and other foreign matter in rotary vacuum filters and filter presses. Activated carbon is required to decolor at the appropriate temperature.

6. Ion exchange process of sorghum cassava corn rice syrup processing plant

Tiny foreign bodies and unpleasant odors are removed by ion exchangers. The device is used for high-quality products.

7. Evaporation process of sorghum cassava corn rice syrup processing plant

Glucose is completely cleaned through a safety filter and then sent to the evaporator for concentration to achieve the required DS, as the final product sorghum cassava corn rice glucose syrup.