Screw press dewatering equipment

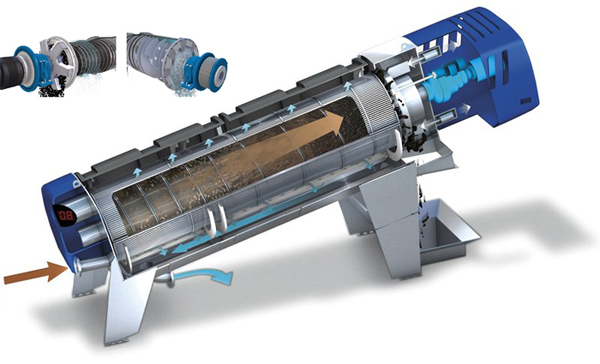

The working process of the industrial screw press machine is: the conveying screw of the press pushes the material entering the tank to the pressing screw. The pitch of the pressing screw is reduced and the shaft diameter is increased. Under the action of the resistance, liquid (juice) contained in the material is squeezed out. The extruded liquid flows out of the sieve hole and is focused on the juice hopper.

The pomace after pressing is discharged outside the machine through the end of the sieve cylinder and the cone, and a spring is arranged at the rear of the cone. By adjusting the preloading force and position of the spring, the displacement resistance and the size of the slag opening can be changed. Adjust the dryness and wetness of the press. The feeding box, sieve cylinder and spiral of the industrial screw press machine are composed of high quality acid and alkali resistant 304 stainless steel.

Main features of the industrial screw press:

1. The shaftless screw is used, the contact surface of the material is small, and the friction is low, which can improve the extrusion efficiency. And there is no clogging and entanglement;

2. The industrial screw press is made of stainless steel, with high strength, good corrosion resistance and long service life;

3. The drive unit adopts the shaft-mounted direct drive mode, which is stable and reliable operation;

4. The outlet is provided with a spring baffle to increase the pressing force and the dehydration rate;

5. In addition to the inlet and outlet, the rest part of industrial screw press adopts a sealed structure, and the environment is clean and hygienic.

Screw press dewatering equipment uses:

This equipment is suitable for dewatering living garbage, water hyacinth, fruit pulp, plastic, chemical, discarded vegetable leaves, and waste waste containing long fiber material stems, so as to reduce the water content and volume in the press material as well as reducing the gas and land occupied by the press material in the process of incineration and landfill.

The middle part of the screw press dewatering equipment is provided with a feeding box, and the material to be dehydrated is sent into the box, and the juice squeezed by the spiral flows into the juice tray through the sieve cylinder, and then flows out from the juice outlet tube. The dehydrated slag cake is discharged through the outlet at the end of the sieve cylinder.

Working process of the screw press dewatering equipment:

The conveying screw pushes the material entering the tank to the pressing screw, due to the pitch of the pressing screw is reduced and the shaft diameter is increased, the liquid (juice) contained in the material is squeezed out under the action of the screen wall and the cone-shaped resistance. The extruded liquid flows out of the sieve hole and is concentrated in the juice hopper. The pressed pomace is discharged out of the machine between the end of the sieve cylinder and the cone. The rear part of the screw press dewatering equipment is equipped with a spring. By adjusting the preloading force and position of the spring, the displacement resistance and the size of the slag opening can be changed to adjust the dryness and wetness of the press. The 5, 10, 20 ton/hour press is a double helix,rotating in opposite directions, the pressing force on the material is large and uniform, and the taper of the tap hole is controlled by the hydraulic cylinder. The oil pressure can be adjusted to change the pressing effect on the material, and the juice rate can be adjusted. The machine can also be used for solid-liquid separation of other materials, the effect of which has a certain difference due to the different quality of materials. The feeding box, sieve cylinder and screw of the screw press dewatering equipment are made of high quality acid and alkali resistant 304 stainless steel.

Product manual:

1. Extract juice from all kinds of fruit and vegetables such as skin residue, sea buckthorn fruit, broken ginger and bamboo shoots;

2. Dehydration of rice bran distiller's grains after fermentation, cassava residue after biogas fermentation; dehydration of Gynostemma pentaphyllum, stevia, Chinese cabbage, urtica, celery, slag, chrysanthemum, etc.; screw press dewatering equipment can also be used for dehydration of wood, wheat straw, straw, reed, etc.;

3. Press and dewatering in the environmental protection industry such as garbage in the vegetable market and household garbage;

Equipment composition:

The screw press dewatering equipment mainly consists of frame, feeding part, pressing part,transmission part and electric control part. The double helix includes a reversely rotating conveying screw and a pressing screw; the single screw press has a powerful feeding device and a retaining device, and the screw is divided into the feeding screw,the pressing screw, and the squeezing screw.

Working principle of screw press dewatering machine

Concentration: when the screw drives the shaft to rotate, the multiple solid lamination located on the periphery of the driving shaft moves relatively. Under the action of gravity, water is filtered out from the relatively moving lamination gap to achieve rapid concentration.

Dehydration: The concentrated sludge moves forward as the spiral shaft rotates. Along the outlet direction of the mud-cake, the screw pitch of the spiral axis gradually decreased, the gap between the ring and the ring gradually decreased, and the volume of the spiral cavity kept shrinking. Under the action of the back pressure plate at the outlet of the screw press dewatering machine, the internal pressure gradually increased. Driven by the continuous operation of the screw driving shaft, the water in the sludge was extruded and discharged, and the solid content of the filter cake was continuously increased, finally achieving continuous dewatering of the sludge.

Self-cleaning: The rotation of screw shaft drives the moving ring to rotate continuously. The screw press dewatering machine realizes the continuous self-cleaning process by moving the fixed ring and the moving ring, thus avoiding the common blockage problem of traditional water extractor.

Application of screw press dewatering machine

The dehydration of wine lees, fruit dregs, pharmaceutical dregs and cassava dregs can greatly reduce the burden of the dryer, greatly increase the output and greatly reduce energy consumption. It is an essential treatment equipment before drying of high wet materials.

Main structure introduction

1.Screw

Screw press dewatering machine consists of a joint thread and a collar alternately sleeved on the screw shaft. Each thread and collar are fixed into the screw shaft. In addition to the three-section isometric continuous thread in the first section (feeding zone),the other sections are single-turn open type. The pitch of each section in screw press dewatering machine is different, gradually decreasing from the low pressure side to the high pressure side, and the diameter of the hub is gradually increased. Large to increase the pressure to squeeze out the moisture in the rubber.

2.Shell

It consists of a scorpion plate composed of cages fixed on the skeleton. The scorpion board is divided into 8 sections, each of which varies in length. The cylinder has an inner diameter of 18 inches and is bolted in two halves on the vertical centerline for easy removal during cleaning and maintenance. The cages constituting the rafters are separated by spring pieces to form a longitudinal slit to allow moisture to flow out. A scraper in screw press dewatering machine is arranged on the upper and lower sides of the cylinder, corresponding to the position of the collar on the screw, and the function is to prevent the rubber from rotating with the screw, forcing the rubber to change the direction and position of the advancement, and forming a loose porous shape to Conducive to drying.