The sixth generation 6SF series straight cut crystal vermicelli (piece) production line

1. Advanced equipment and excellent quality

The 6SF series crystal vermicelli machine is the equipment after years of painstaking research by the scientific research personnel of Kaifeng Star Company. It uses starch as the raw material to produce crystal vermicelli (strips), and the equipment structure matches the production process requirements of the crystal vermicelli (strips). In the production, a large-capacity mixer is used for mixing, frequency conversion speed adjustment is used to adjust the thickness of the powder, and frequency conversion speed adjustment is used to adjust the time required for aging. The straight bar cutting method makes the bar shape uniform. Entrained and shaped and dried to make the dried noodles (bars) straight. The crystal fans produced are of high quality, beautiful appearance, crystal clear and translucent, resistant to boiling, foaming, not muddy soup, continuous sticking, and non-sticking. It is clean and hygienic, with a delicate taste and a smooth entrance. Spiral stirring replaces frame stirring, with fast response speed, high control accuracy, flexible switching mode, good power saving efficiency, stable operation performance, fewer equipment failures, and long service life. New technical innovation highlights are added:

A. The cold storage is widened and lengthened, which extends the freezing and aging time of the powder belt, and the toughness of the product is stronger;

B. The oven is higher, the number of drying layers is increased, the drying time is prolonged, and the product tendons are better;

C. Using vacuum stirring, the product has fewer bubbles and higher brightness;

D. More applicable raw materials, wider adjustable and controllable space;

E. The equipment has lower energy consumption and greater profit margins;

F. Technical upgrades have greatly improved product productivity, and the return on profits is very significant. The whole machine has unique design, advanced technology, compact equipment, energy saving and consumption reduction, small footprint, high degree of automation, less production and labor, uniform terminal product quality, high yield, high return and profitability.

The salient features of the equipment are: changing the traditional extrusion leaking scoop type, outdoor hanging pole cooling production process, adopting straight cutting, entraining forming, constant temperature, constant humidity, low temperature, freezing, not affected by the seasonal climate, and can achieve continuity The uninterrupted assembly line operation overcomes many shortcomings of traditional production and is the production and processing equipment for vermicelli. The significant advantages of the equipment include: fully automatic, fully enclosed, multi-functional, automatic feeding, automatic temperature control and other integrated production, with high-tech content, high added value, and pure natural production technology. ) The choice of large-scale, international and original ecological production enterprises.

2. Green product quality

The production line of the sixth-generation 6SF series crystal vermicelli (strip), from starch into the machine to the finished vermicelli, is fully enclosed and fully automated. The entire production process does not use any additives (alum), preservatives and food colorings. Pollution, pollution-free, and fully embody the production concept of green, environmental protection, natural, safe, high-quality, and nutritious. Various types of crystal vermicelli can be produced according to different production areas, different market needs, and different consumer groups. The appearance of the produced products is regular and regular. Same shape, uniform color, crystal clear, clean and hygienic, easy to store and easy to transport. It is resistant to cooking and foaming, and has a refreshing taste. It is a healthy nutritious food, green food, safe food, and rest assured food. The equipment is not affected by weather and season during the production process. The yield rate is as high as 95%. The equipment runs at low speed, and the line speed is around (3.5 m/min), so the operation is convenient and safe. Through the actual application in the production process, the output of this machine has increased by more than 25% compared with similar products on the market without increasing the original size and ensuring product quality.

Three, industry-leading technology, energy-saving, fully automated advantages

1. Fully automatic vacuuming process, the brightness of the product is improved, the bubbles are reduced, and it is resistant to boiling and foaming.

2. The stainless steel paste scraper is formed to reduce the thickness error and ensure that the thickness of the product is completely controllable.

3. The steel belt is driven by the whole chain, which improves the flatness of the service life of the steel belt and the mesh belt (driven by the conveyor belt) and the flatness of the powder belt.

4. Aging use once at room temperature, closed brake, constant temperature and humidity, natural aging, automatically transfer to low temperature aging system.

5. The drying box adopts multi-layer drying, the heat utilization rate is improved, and the steam heat exchanger waste heat reuse device is added, so it is more energy-saving.

6. From the raw material entering the machine to the finished vermicelli exit, all adopt a closed type and programmed operation.

7. No pollution during production, meeting environmental and sanitary requirements.

8. Process flow: preheating → spiral stirring (constant temperature storage) → vacuum stirring → scraper cutting forming → steaming (steam) → cooling → separation → room temperature aging → low temperature aging (cold storage) → vertical cutting → low temperature Air volume setting drying → cooling (cold air intake) → fixed length cross cutting → packaging.

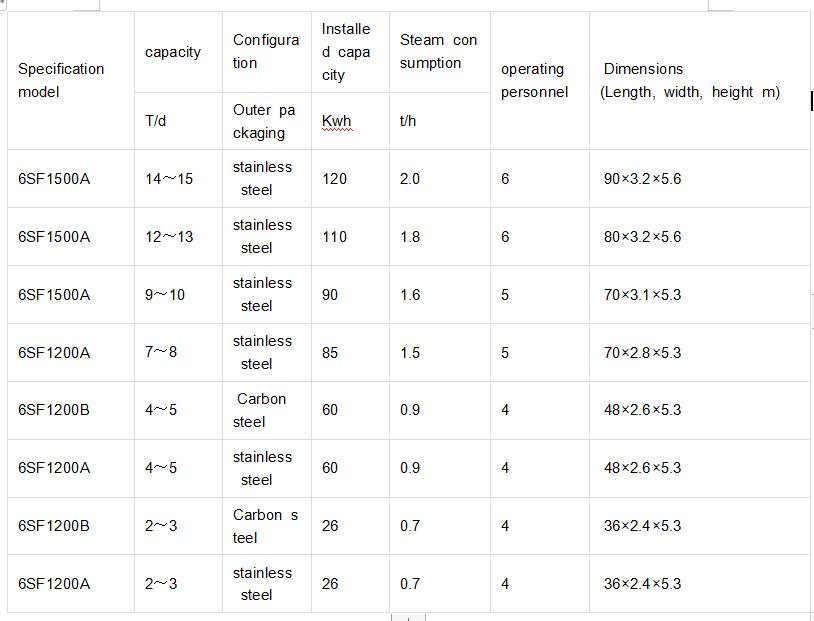

Four, 6SF series crystal fan machine parameter table

V. Project profit analysis: (Take the 15-ton daily crystal vermicelli production line as an example)

1. Personnel: 5 people/shift, two-shift system, 5 people×2 shifts×80 yuan/person ÷ 15 tons = 67 yuan per ton labor cost, 190 yuan per ton packaging cost, totaling 247 yuan

2. Electricity cost: installed capacity of 120kwh, boiler of 27kwh, electricity consumption per hour (120+27) × 24 hours × 0.75 yuan/kw ÷ 15 tons = 176.4 yuan

3. Natural gas consumption: 2.0T/h of steam needs to be equipped with a 4T boiler with 2500 cubic meters of natural gas per day, 2.9 yuan per cubic meter of natural gas per cubic meter, and the amount is 2500×2.9÷15=483.3 yuan

4. Water volume: 2T/h, water fee 5 yuan/ton, 2×24×5÷15=16 yuan

5. Direct production costs: 247 yuan (labor) + 176.4 yuan (electricity) + 483.3 yuan (natural gas) + 16 yuan (water) = 922.7 yuan

6. Profit: The direct production cost plus the cost of raw materials and packaging materials is the comprehensive cost of the product, and other expenses (depreciation, bank interest, sales expenses, taxes, etc.) are calculated based on their respective local conditions.

6. Infrastructure requirements:

1. Workshop design: (minimum required size)

A. 14-15 tons vermicelli production line: 95 meters long, 8 meters wide, 6 meters high

B. 12-13 tons vermicelli production line: 85 meters long, 8 meters wide, 6 meters high

C. 9-10 tons vermicelli production line: 75 meters long, 8 meters wide, 6 meters high

D. 7--8 tons vermicelli production line: 75 meters long, 7 meters wide, 6 meters high

E. 4--5 tons vermicelli production line: 50 meters long, 7 meters wide and 6 meters high

F, 2--3 tons of vermicelli machine production line: 40 meters long, 7 meters wide, 6 meters high

2. The indoor floor is flat, and the anchor screws can be tightened;

3. Ventilation and light transmission, no dust pollution, convenient water supply and drainage, equipped with water, electricity and steam matching the equipment.

7. The company's pre-sales and after-sales service

Our company produces various equipment such as crystal vermicelli machine, vermicelli machine, vermicelli machine, hot-dried noodle machine, rice noodle machine, potato starch equipment, wheat starch equipment, airflow dryer and other equipment. All of them are free for customers to design the plant layout and market. Analysis, feasibility study report and other pre-sale services. The company's high-level professional installation technicians go to the user site to install the test machine to ensure the quality of the whole machine installation; provide free training of technical operators for users to achieve independent operation and normal production shall prevail; establish files for users and follow up services at any time. The company conducts year-round tracking services for the operation status of the sold equipment, user needs and opinions, and if any problems are found, the company’s professional and technical personnel will come to the door to solve them in time; the equipment will be guaranteed for one year from the date of commissioning, and the company will provide lifetime service. Respond, 365 days of uninterrupted technical support, purchased equipment can be upgraded with the company's latest products, long-term supply of various accessories on the equipment (cost fees) and other after-sales services.