We are a professional starch syrup production machine supplier, specialized in manufacturing the syrup production machine, our high fructose syrup processing machine,glucose fructose syrup production machine,maltose syrup process machine capacity can be large and small, from 3-5tons per day to annual capacity 10 million tons, all is a complete set of syrup production machine, from raw material(usually starch or flour) handling to the final fructose syrup storage, fully automatic completed by our machine. The syrup production machine design and manufacturer like size, volume mainly according to the capacity demand, more details design requests about your syrup production machine, you can discuss with our engineer, then we can made machine for you as your requests.

Manufacturer by KaiFeng sida Company, about maltose syrup processing machine, we can offer:

1. Complete set energy saving syrup production equipment, according to client's different demands offer personal production plan, we will design the most ecnomic benefit and high efficiency technical plan for you.

2. Automatic control system: the advanced nature of control system is the guarantee of high quality products of syrup production. Continuous and stable production can reduce the production cost.

3. syrup production plant installation, adjust and operation training: all equipments through strict quality testing, after the test passes, Doing Company engineer will adjust the equipments and train the operation people, make sure the production technology reach the requests and your syrup production operation smoothly.

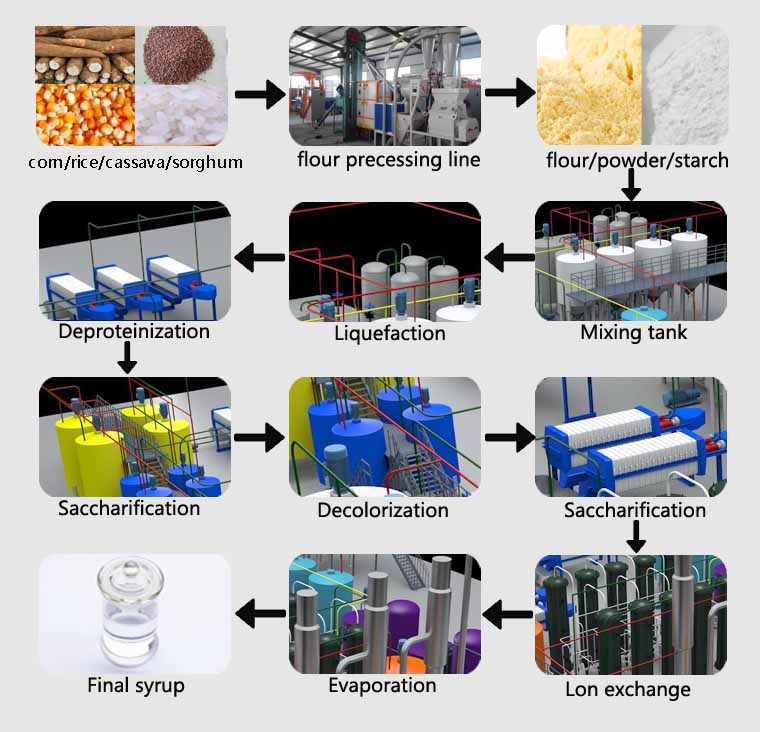

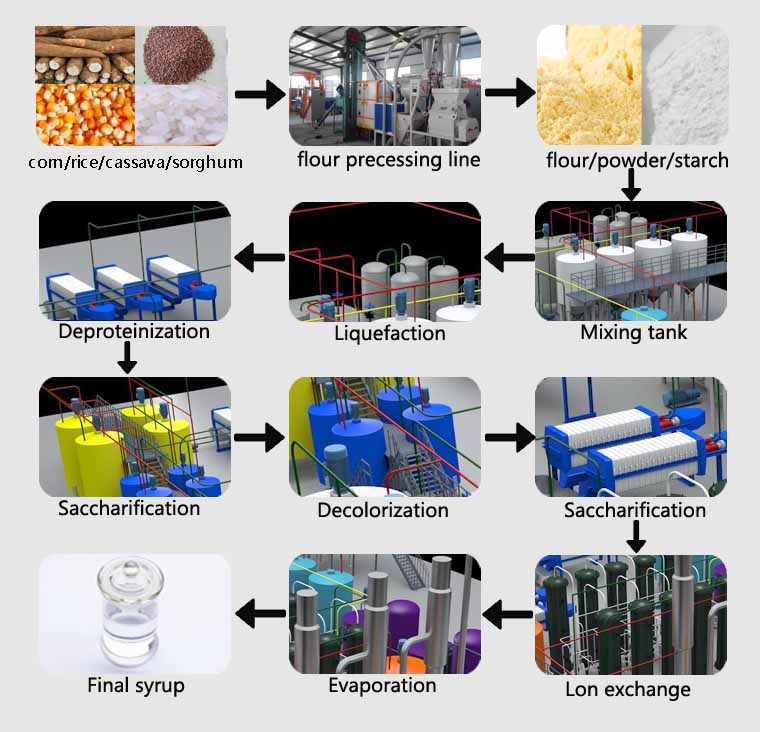

Maltose syrup process machine technology description:

1. Mixing slurry unit during the maltose syrup process:

Put the rice powder and water into the mixing tank, then put the enzyme, keep on particular standard temperature, waiting the starch reaction for some time, then can be transported to next work section.

2. Ejector liquefaction unit:

The mixed rice pwoder milk is sent to buffer tank then liquefied by ejector(also named jet cooker) with the aid of enzyme at high temperature in regular time for maltose syrup process.

Maltose syrup process machine

Maltose syrup process machine

3. Filter press deproteinization:

Because of inside the rice slurry still have too much protein, so the slurry need to pumping into the press filter, after press the slurry, the syrup will flow into the slot, then the protein will stay inside the filter machine. Usually adopt the plate frame filter press machine for maltose syrup process, and after this process, there will be many protein cake can be sale as animal feed.

4. Saccharification:

The liquefied material is sent to enzyme saccharification tank for reaction. Maintain at specific temperature for some time, the syrup will transfer to maltose syrup, this saccharification process is important for the quality of matose syrup process.

5. Decolorization:

After LAB testing, all the maltose syrup pumping into the decoloration tanks, at uniform temperature, mix with activated carbon, usually it have to make twice to get pure and colorless maltose syrup.

6. Filter press decarburization:

The maltose syrup with activated carbon will be pumped into the filter press machine, after press the clean maltose syrup will flow into the buffer tank, the activated carbon will stay inside the filter. This decolorization & decarburization process actually is integrated for maltose syrup process, aimed to get colorless and transparent syrup.

maltose syrup processing line flow chart

7. Ion exchange process:

The clean maltose syrup pumping into the ion exchange columns, inside the column the resin will attract all the cation and anion and other small electron, then will get very pure glucose syrup for people eating. This equipment is essential high quality maltose syrup process.

8. Concentration and evaporation:

Under vacuum conditions, the maltose syrup is heated for evaporation. When the maltose syrup process concentration reaches the requests standard, then it cools the temperature and enters into the final product tank for storage. The finished product can be high maltose syrup and super high maltose syrup.

Above all is the simple description for maltose syrup process machine, we are the professional maltose syrup process machine manufacturer,and we can provide you the feasibility program according to your demand for maltose syrup production technology.

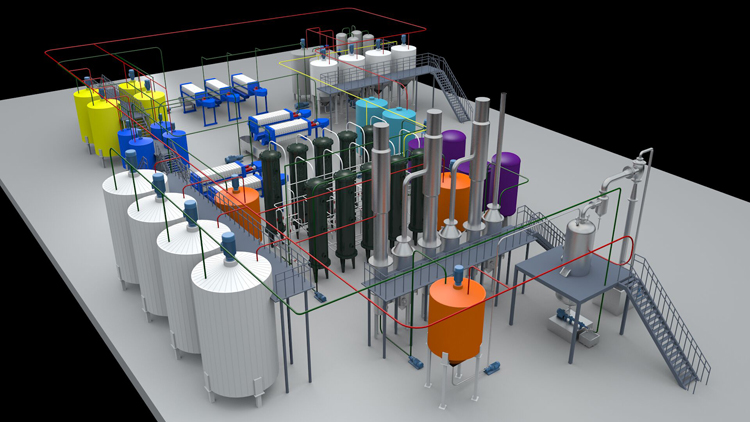

maltose syrup processing line

Our completed projects in Europe、America 、Africa Nigeria, Malaysia、Tanzania, you can be visited.If you need corn&rice syrup processing machine、fructose syrup processing machine、Maltose Syrup Processing machine、 Glucose Syrup Processing machine、starch and flour processing machine and other problems,Please leave a message under the website,Or send email, or consult our online customer service. We will answer your questions immediately. Welcome to the consultation.The Company manager go to your country, you can to talk with manager.