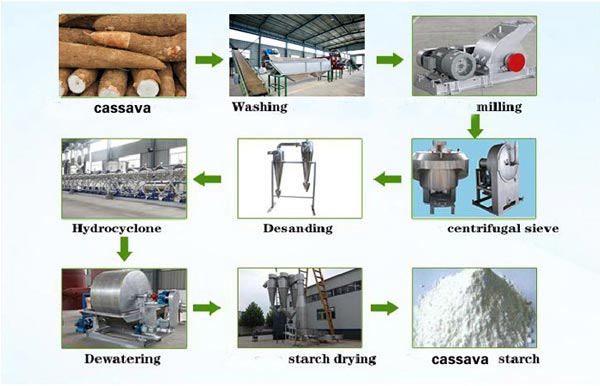

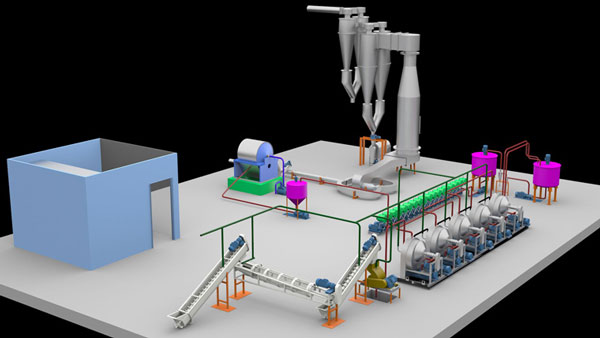

Cassava Flour production machine flow process chart

Cassava Flour production machine flow process chart

- Next is sand removal section. Fully remove the sand impurity particles in the starch to ensure the taste and quality of the starch in tapioca flour production line.

The mainly equipped equipment in this section is: sand remover.

Characteristics of the section: small size, large handling capacity, ensure the sand impurities in starch br removed thoroughly removed in tapioca flour production line.

- Then starch slurry need to be further concentrated and refined. Replace the traditional precipitation process in tapioca flour production line, which is highly concentrated and refined. To separate non-starch substances (protein, cell sap and other soluble and insoluble impurities), and improve the whiteness quality of starch.

The mainly equipped machinery in this section: hydrocyclone station.

Section characteristics: Mathematical simulation modeling, effectively separating non-starch substances such as yellow powder, oil powder and peotein in starch, easy to operate, easy to maintain, no blocking, and long service life.

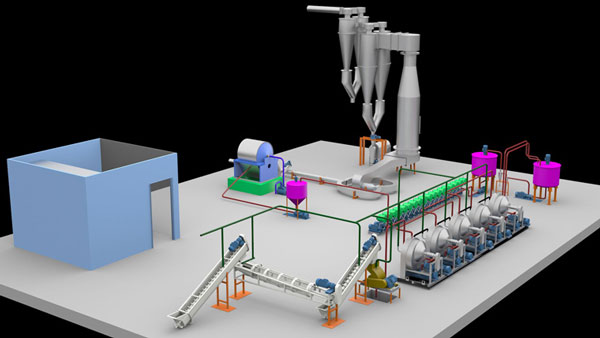

cassava flour extraction machine

- Starch milk content excess water need to be dehydrated. The refined starch has high water content, peeler centrifuge can effectively reduce the water content of the starch and facilitate the drying in next step of tapioca flour production line.

The equipment mainly equipped in this section: peeler centrifuge.

Section characteristics: high dehydration rate which faciliate drying, high efficiency and energy saving, consistent and stable operation, convenient operation, reduce labor, decrease labor intensity.

- Wet starch is then dried and packed. Quickly remove moisture from the wet starch in tapioca flour production line.

The mainly equipped machinery in this section: airflow flash dryer.

Section characteristics: large drying strength, strong evaporation capacity, short drying time, no pollution, good starch quality.

Tapioca flour processing machine

Mechanized processing characteristics

1. The introduction of Europe advanced technology, combined with traditional technology, starch extraction rate, starch filtration rate, starch precision, starch whiteness have been greatly improved, and recognized by market users.

2. During the mechanized production process, the key starch processing steps in tapioca flour production line are carried out in fully enclosed equipment, the sanitary conditions are guaranteed, the external pollution is reduced, the degree of oxidation of the starch material is reduced, and the quality of the finished starch product thus can be ensured.

3. The degree of automation in tapioca flour production line is significantly improved, so that the operation becomes convenient and time-saving. In addition, the intelligent operating system greatly reduces the labor intensity. Low energy consumption and low water consumption reduces production costs.

Cassava flour processing line

sdia Company as an professional starch processing machinery manufacturer, we can provide tapioca flour production line with the following production capacity (daily treatment volume is calculated in 24 hours):

200KG/hour tapioca flour production line, daily processing cassava raw material: about 20T;

500KG/hour production line, daily processing cassava raw material: about 50T;

1000KG/hour production line, daily processing cassava raw material: about 100T;

1500KG/hour tapioca flour production line, daily processing cassava raw material: about 150T;

2500KG / hour production line, daily processing cassava raw material about: 240T;

5000KG/hour tapioca flour production line, daily processing cassava raw material: about 480T;

10000KG/hour production line, daily processing cassava raw material: about 960T.