Corn glucose syrup production equipment

Release Time:2020-07-14 17:34Author:sd888Source:未知

Any questions about the product can be communicated with us at any time!

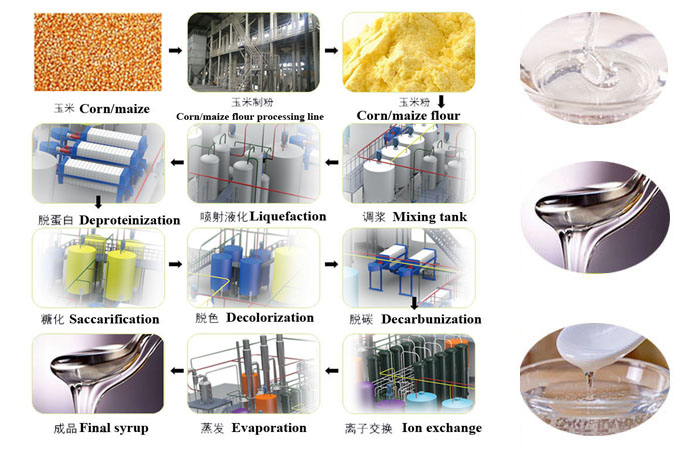

The traditional method of corn glucose syrup production equipment is to use corn starch to produce glucose syrup. Now, our company has new technology, we can directly produce glucose syrup from corn (corn) in corn glucose syrup production equipment.

Our company's corn syrup production equipment technology is advanced. The main corn syrup production equipment and main equipment are as follows:

1. Corn flour production process of corn glucose syrup production plant

The washed corn will first be separated into germs, and then the corn flour will be ground into corn flour by dry milling. After repeated grinding and sieving, corn flour of the required size is obtained to produce glucose syrup.

2. Corn flour slurry pulping process of corn glucose syrup production plant

Mix rice flour and water to get a slurry of the correct density. Then add amylase and maintain the temperature for a specific period of time, so that the rice flour absorbs enough water.

3. Liquefaction process of corn glucose syrup production plant

The liquefaction process converts the starch inside the rice flour into liquid dextrin. The material will be sprayed at high temperature by spraying cookware. With the help of amylase and steam, starch will be quickly converted into liquid dextrin.

4. Deproteinization process of corn glucose syrup production plant

The deproteinization process is to separate rice protein and other solid impurities from the liquid dextrin by a filter press. Liquid dextrin will be pumped to the next process, and rice protein will be sold. .

The by-product rice protein (feed grade) is a high-grade protein additive used in the manufacture of animal feed.

5. Saccharification process of corn glucose syrup production plant

The saccharification process is to convert the liquid dextrin into glucose syrup with the required DE value by the glucoamylase in the tank. This process should be run for a few hours at a specific temperature. This process is to get thick and yellow glucose syrup.

6. Decolorization process of corn syrup production plant

The decolorization process is to remove the color of glucose syrup by activated carbon. The glucose syrup that achieves the required DE will be pumped from the saccharification tank into the decolorization tank and mixed with activated carbon at an appropriate temperature.

7. Decarbonization process of corn glucose syrup production plant

In the decarburization process, activated carbon is separated from glucose syrup by a filter press to obtain a clear glucose syrup.

The glucose syrup will flow into the tank and transfer tank for the next step. Activated carbon will be retained.

8. Ion exchange process of corn glucose syrup production plant

The ion exchange process uses resin to remove tiny foreign bodies and unpleasant odors, thereby obtaining high-quality pure glucose syrup.

After working for a few days, the resin needs to be regenerated by acid washing and alkali washing

9. Evaporation process of corn glucose syrup production plant

The evaporation process is to evaporate the water in the glucose syrup to increase the DS of the glucose syrup.

Usually it requires multi-effect evaporator to work with single-effect evaporator to produce high DS glucose syrup.

10. Storage of the final product in the corn glucose syrup production plant