Cassava syrup refers to the direct production of high-malt syrup using cassava as raw material, and the cassava starch has no peculiar smell. It is suitable for products requiring fine-tuned odor, such as food and cosmetics.

Glucose syrup is a kind of starch syrup produced by using starch as a raw material under the action of enzymes or acids. The main components are glucose, maltose, maltotriose, maltotetraose and above. Also known as liquid glucose, glucose syrup.

Also known as dextrose. A monosaccharide, hexose containing aldehyde groups. The solid state is white crystals, slightly soluble in water, with optical rotation, and its aqueous solution rotates to the right. It exists widely in the body and is a component of certain disaccharides (such as sucrose, maltose, etc.) and polysaccharides (such as starch, cellulose, etc.). Glucose syrup is produced by hydrolysis of starch, and in the 1960s, microbial enzymatic method was used to produce glucose. This is a major innovation and has obvious advantages over acid hydrolysis. The raw materials do not need to be refined in the production, no acid and pressure resistant equipment is needed, and the sugar liquid has no bitter taste, and the sugar production rate is high. In the food industry, glucose is processed by isomerase to produce fructose, especially fructose syrup containing 42% fructose. Its sweetness is the same as sucrose. It has become an important product in the current sugar industry.

Fructose syrup

Soft drinks: Fructose syrup is widely used in the production of beverages, accounting for about 75% of the applications in the beverage field. Because of its high solubility and cold sweetness, and the fact that fructose syrup contains fructose, it has a fruity fragrance and is close to natural fruit juice, which makes the finished product cool and refreshing. It can be used in refreshing beverages such as carbonated beverages, fruit juice beverages, sports drinks and so on.

Maltose syrup

Hard candy: Maltose syrup has a high viscosity and anti-crystallinity. It is used in the production of hard candy, which can make the candy less prone to frizziness and anti-sand, and extend the shelf life. For hard candy, the lighter the color of the hard candy, the more transparent the candy, and the more transparent the candy, the more high-end. Maltose syrup has good heat resistance and high boiling temperature, which can make the produced candy light in color and good in transparency. And because of the low hygroscopicity, excellent water retention and good fluidity of maltose syrup, it can maintain the proper moisture of the candy, prevent the water from dispersing, prevent the candy from being too hard, and also prevent the candy from absorbing a lot of water and making the candy too soft, so in the candy industry The application of maltose syrup is better than glucose syrup.

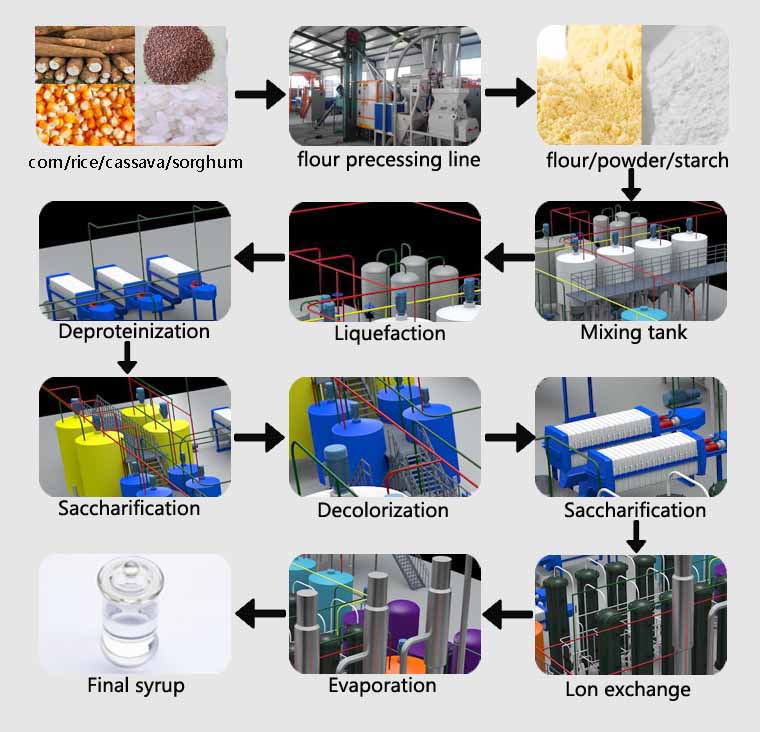

Cassava processing syrup process

Process overview:

Glucose syrup is a starch syrup produced from starch as a raw material under the action of enzymes or acids.

Mix starch with water to 17-19. Be. About pH, adjust the pH around 5.0-6.0, add amylase and liquefy through high temperature. The liquefied slurry is filtered, and the filtrate is saccharified with hydrochloric acid to adjust the pH value. The saccharified solution is decolorized by activated carbon, ion exchange resin, and concentrated into glucose syrup.

Process details:

Ø Sizing and liquefaction: starch is adjusted to 17-19 with water. Be. The pH is adjusted to about 5.0-6.0. After the slurry is adjusted, the high-temperature liquefaction enzyme is added, and the slurry pump reaches the injection liquefier. The temperature after injection is controlled at 100-110°C, and the temperature is maintained for 60 minutes, and then the second injection is 120-125°C. , 5min, flash evaporation to reduce the temperature to about 96 ℃, heat preservation for 2 hours;

Ø Saccharification: saccharification of sugar liquid liquefied to a certain DE value by the action of saccharification enzymes, decomposing into syrup with glucose, fructose, sucrose, maltose, etc. as the main components, after reaching the required DE value, it is transferred to the next process;

Ø Decolorization of sugar solution: Using activated carbon adsorption, through two countercurrent decolorization processes, the color of syrup is removed, and some of the protein and fat are removed by adsorption.

Ø Ion exchange: adjust the temperature and PH value of the syrup, cool down before the exchange, the syrup is pumped into the ion exchange system for desalination, and the ash content of the syrup is removed through the cationic resin and anionic resin.

Ø Concentration: After desalination, the syrup is heated and evaporated under vacuum to make the concentration of the syrup reach the range required by the process, reduce the temperature, and send it to the finished process for filling, which is glucose syrup;

The key equipment of this process:

High temperature ejector, steam recovery device, ion exchange device, concentration tower unit, PLC automatic control system.

3. Technical characteristics:

1. Adopt high-temperature resistant liquefaction enzyme and one-shot spray liquefaction process to accurately control the temperature, and starch liquefaction is sufficient without regeneration.

2. Adopt efficient heat exchange and steam recovery technology to save energy;

3. Flow activated carbon decolorization process, good decolorization effect, high degree of automation, to ensure the color of the finished product.

4. Optional ion exchange column sugar liquid refining process, fully remove the ash in the syrup, and raise the temperature of the finished product.

5. Small waste water discharge, low COD value, low pollution, low environmental protection treatment cost.

Provide a full set of starch sugar design solutions

We provide different professional design solutions according to the different industries of each customer, different raw materials, and different needs of products, to ensure that each set of technology can meet the interests of each customer, and to design a set of efficient and economical technical solutions for customers.

Provide technical service scope

According to customer requirements, we provide engineering service work from technical scheme design, process technical drawings, equipment manufacturing, on-site installation, on-site commissioning, on-site training, and on-site training to ensure that qualified products are produced on the production line handed over to customers.