cassava starch processing machine in Nigeria

Release Time:2019-01-17 11:25Author:cassava machineSource:https://www.cndamachines.com/

Any questions about the product can be communicated with us at any time!

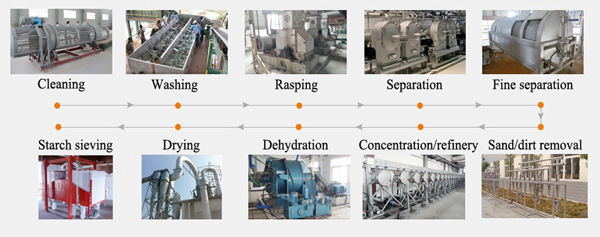

Cassava starch processing mill plant automatically complete the whole process of cleaning, crushing, filtering, fine filtration, purification, concentration and refining, dehydration, drying and packaging of cassava starch. The production line has the following characteristics:

01 The whole process by mechanization to completes the whole production process in cassava starch processing mill plant from cassava cleaning to finished dry starch production.

02 Equipment configuration is complete, high degree of automation

03 Equipment material is mainly made of stainless steel, guarantee starch quality

04 The finished product is powdered dry starch with good quality.

05 Cassava starch processing mill plant with short starch processing time

06 The degree of automation is relatively high, the number of people requests small, and the labor intensity is small.

Cassava starch processing mill plant common equipments and its functions:

01- Multi stage cleaning: Cleaning is the key link of cassava processing, efficiency cleaning ensure the starch has a good taste, which is the basic quality of starch quality.

Commonly used cleaning equipments are: new squirrel cage cleaning machine(also named dry sieve), which effectively removes the dirt, sand and doped small stones, weeds, etc. attached to the cassava during the rotation process. Paddle washing machine, further cleaning and rinsing, improve the cleanliness of cassava cleaning, and have a peeling effect. In general, the cleaning of cassava in cassava starch processing mill should be combined by these two devices to achieve the desired results.

02- Using cutting machine and rasper to complete the comminution of cassava, get higher starch extraction rate than commonly crushing machine.

03- Adopt centrifuge sieve machine for separation of starch slurry and cassava residue. Doing Company centrifuge sieve machine equipped with automatic front and back washing system to guarantee good sieve penetration and ensure high efficiency operation of equipment

04- Fine filtration to further remove fine slag from starch slurry, get a good starch separation effect.

05- Sand removal/desilting: According to the principle of specific gravity separation, the starch emulsion is pumped into the cyclone sand remover with a pressure pump, the bottom is discharge sand, the top is discharged the slurry, then the fine sand are removed from starch slurry to further improve the starch precision.

06- Hydrocyclone station: The starch slurry is further concentrated and refined to remove non-starch components such as protein, fat to improve the quality of the starch.

07- Starch Dehydration: The refined and concentrated cassava starch slurry is dewatered by a peeler centrifuge to achieve the moisture content (less than 40%) required for drying, after dewatering by the centrifuge, the moisture content of the cassava starch can reach 36.5%, it can save power consumption for starch drying in cassava starch processing mill.

08- Drying, dry with low temperature and high air volume. The wet starch enters the drying pipe from the powder feeding machine, and the fresh air is heated by the radiator to be mixed with the wet starch sent to the drying pipe by the powdering machine, and the dried finished cassava starch is obtained by heating exchanger.

Then after drying, send dry cassava starch to the sieving machine, then can be packaged as goods for sale.