how to make cassava flour

Release Time:2019-01-17 11:25Author:sd888Source:https://www.cndamachines.com/

Any questions about the product can be communicated with us at any time!

Next, we will introduce what kind of equipment does the cassava flour processing line have in the cassava flour factory. The processing line needs 5 steps as followings.

Step 1. Cassava cleaning and washing: usually use two machines dry sieve and paddle washer in cassava flour factory which can clean cassava entirely. We all know that cassava is bigger than other potatoes, dry sieve main function is remove the dirt, sand, or other impurities which mixed with cassava. Paddle washer mixed cassava with water, fully remove the soil in cassava surface.

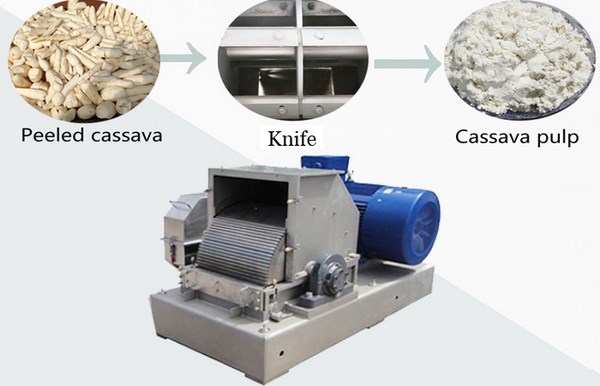

Step 2. Cassava crushing by rasper: Different with traditional hammer crusher, Company rasper used for cassava crushing can get better crushing effect, because of rasper adopted, there is no need the peeling machine in cassava flour factory, after crushing we get the liquid, which will through the desanding and dewatering process, can guarantee the finished cassava flour no poison, high quality, taste better. Of course, we also can manufacture the cassava peeling machine for you.

Step 3. Desanding: the liquid cassava flour through the specialized desanding machine to remove the impurities to get clean cassava flour liquid in cassava flour factory to make sure finished cassava flour taste good, whitness.

Step 4. Using plate and frame filter press to dewater. Plate-frame filter press is an effective type of dewatering equipment. It is used for various solid-liquid separation. Filter press is for large filtration plants that requires a high degree of automation or centralized control, large capacity.

The whole machine in the cassava flour factory is designed with integration of machine, electricity and liquid, which can realize automatic pressing, filtering, draining, squeezing, loosening and so on with a high degree of automation, large production capacity, small filter cake and high output. After using Plate-Frame, the cassava flour water content less than 40%.

Step 5. After air drying, cassava flour water content will be 12%-14%, reach the requests. Air dryer is the idea choice for flour production enterprise of our cassava flour factory. Then the cassava flour can be send to sieving and packing process.

As you can see, the equipment in the cassava flour factory including dry sieve, paddle washing machine, cassava peeling machine, rasper, Plate-Frame filter press, and flash dryer. Cassava flour production is well-developed as an organized agricultural crop in many countries. It has well-established multiplication and processing techniques for food products and cattle feed. Cassava is grown throughout the year, making it preferable to the seasonal crops of yam, beans or peas. It displays an exceptional ability to adapt to climate change, with a tolerance to low soil fertility, resistance to drought conditions, pests and diseases, and suitability to store its roots for long periods underground even after they mature. Believe after reading this essay, you will have a better understanding on the cassava flour processing line and cassava flour factory.