industrial starch production from cassava pdf

Release Time:2019-05-23 10:59Author:sd888Source:https://www.cndamachines.com/

Any questions about the product can be communicated with us at any time!

project proposal on cassava making, industrial starch production from cassava pdf, processing of cassava into flour,products made from cassava

It is best to use cassava cultivars which contain a low level of cyanogenic compounds, since these are potentially toxic. However, the cyanogenic content of fresh roots is not a serious problem in cassava flour production, since it is almost entirely eliminated during flour processing. Furthermore, Thailand's traditional cassava cultivars do not contain a high level of hydrocyanic acid. Our experiments on dried chips of cassava from nine cultivars found that the hydrocyanic content fell from 13.5-114.7 ppm in the fresh roots to 0.40- 2.37 ppm in the flour. The level varied according to the cultivar and the time of harvest.

Cassava Flour As a Substitute for Wheat Flour

Cassava flour does not contain any gluten. If it is used to replace wheat flour 100%, the quality of the product will be different. A suitable ratio for replacing wheat flour that consumers find acceptable depends on the kind of food.

For example, cassava flour can replace 75% of wheat flour in sponge cakes and chiffon cakes, 50% in butter cakes and cookies, 25% in doughnuts and spaghetti, and 20% in bread ( Fig. 5(837) and Fig. 6(900)). Cassava flour can be used to replace 25 - 50% of the rice starch in noodles, and will make the noodles softer and more elastic ( Fig. 7(1114)).

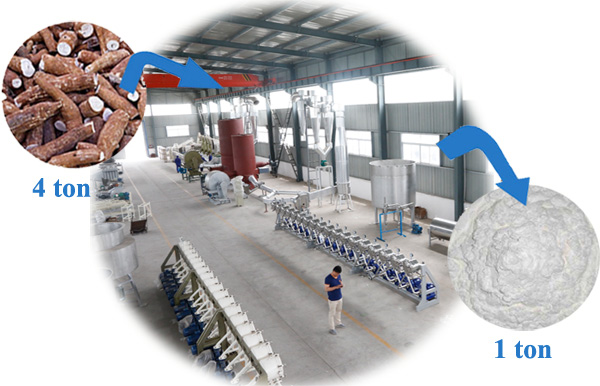

Cassava starch is produced primarily by the wet milling of fresh cassava roots but in some countries such as Thailand it is produced from dry cassava chips. Starch is the main constituent of cassava. About 25% starch may be obtained from mature, good quality tubers. About 60 % starch may be obtained from dry cassava chips and about 10 % dry pulp may be obtained per 100 kg of cassava roots.

Several efforts have been made to develop suitable indigenous machines for cassava processing; this attempt was made to make the cassava mash process more energy-efficient and to meet the Millennium Development Goals (MDGs), aimed at poverty reduction over a stipulated period of time. A suitable machine was developed to handle cassava mash processing in High Quality Cassava Flour (HQCF) production. The development was done by using basic scientific outcomes, engineering discoveries, well-known principles and existing cassava mash handling practices in HQCF production. The development involves survey of existing methods, conceptual design sketches, components design, machine drawings, calculations, prototype fabrication and testing. The laboratory investigations were carried out on handling and materials interactions with the cassava mash containing starch and fibre. Mash flowability on steel, plywood and Aluminum was conducted. Resistance of cassava mash to applied pressure during filtration and expression dewatering was handled with steady volume reduction process. A pressure setting for first stage of dewatering was based on the back pressure crated by spring with a known force. Screw conveying capacity reduction creates pressure as a result of tapered shaft. The parameter settings were determined experimentally before the combination of the operating units. Results of test carried out gave a mash residing time of 7minutes. The emerging mash paste from the screening unit contains 57%mcwb from 72% mcwb cassava mash sample. Further movement of the mash paste was accomplished with continuous variable volume expression dewatering. The final obtained mash cake has a moisture content of 43-48% mcwb. The mash cake formation depends on the strength of the back up spring. Pulverization unit receives mash cake through gravity via conveying tube inclined at 45 degree. A high-speed size reduction unit breaks the mash cake into particles then allows it to flow out into a reciprocating sieve. The machine produces the desired mash of fine particles less than 1mm thickness ready for flash drying. The combined handling movements resulted in using small space, reducing unnecessary human handling, it eliminates drudgery. The prototype was powered with a single 35W electric motor there by minimizing the power requirement; the product obtained compared well with the existing HQCF mash data. The machine product could perform better than the local ones at a reasonable time when commercially adopted.