Corn glucose manufacturing plant

Release Time:2020-07-14 15:42Author:sd888Source:未知

Any questions about the product can be communicated with us at any time!

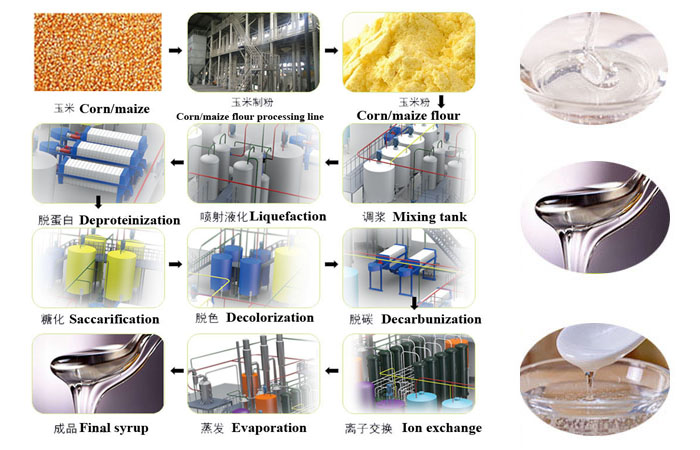

Before converting corn starch into glucose, the starch must be separated from the plant material. This includes removing fiber and protein. Due to the Maillard reaction, the protein produces odor and color. The fiber is insoluble and must be removed to hydrate the starch. The deproteinization process in the corn glucose production plant is usually completed by our plate and frame filter.

The starch needs to be swelled to allow the enzymes to act upon it. When grain is used, sulfur dioxide is added to prevent spoilage. By heating the ground, cleaned feedstock, starch gelatinization takes place: the intermolecular bonds of the starch molecules are broken down, allowing the hydrogen bonding sites to engage more water. This irreversibly dissolves the starch granule, so the chains begin to separate into an amorphous form. This prepares the starch can be used for hydrolysis. So actually this is the first step for corn glucose manufacturing plant process.

Hydrolysis by enzyme:

Glucose syrup can be produced by acid hydrolysis, enzyme hydrolysis, or a combination of the two. However, overall consideration, the enzyme hydrolysis is the best choice, no corrode the equipment, better performance for corn glucose manufacturing plant.

Currently, glucose syrup is mainly produced by first adding the enzyme α-amylase to a mixture of corn starch and water in corn glucose manufacturing plant. α-amylase is secreted by various species of the bacterium Bacillus; the enzyme is isolated from the liquid in which the bacteria are grown. The enzyme breaks the starch into oligosaccharides, which are then broken into glucose molecules by adding the enzyme glucoamylase, known also as "γ-amylase". Glucoamylase is secreted by various species of the fungus Aspergillus; the enzyme is isolated from the liquid in which the fungus is grown. The glucose can then be transformed into fructose by passing the glucose through a column that is loaded with the enzyme D-xylose isomerase, so except the glucose manufacturing plant, we also offer the high fructose corn syrup manufacturing plant.

Separation and purification:

After hydrolysis, the dilute syrup can be passed through ion exchange columns to remove impurities, improving its colour and stability.

Evaporation process in corn glucose manufacturing plant:

The dilute glucose syrup is finally evaporated under vacuum to raise the solids concentration.

Compare the traditional technology, we supplied corn glucose manufacturing plant use double enzyme method can produce large range DE of glucose syrup for different application .