producing glucose syrup for commercialization identify and write in details the technical aspects of

Release Time:2020-07-14 15:35Author:sd888Source:未知

Any questions about the product can be communicated with us at any time!

professional glucose fructose syrup production equipment manufacturer, and can offer glucose fructose syrup production technology to you, also the production plan and installation guidance. Following is the introduction of our glucose fructose syrup production introduction:

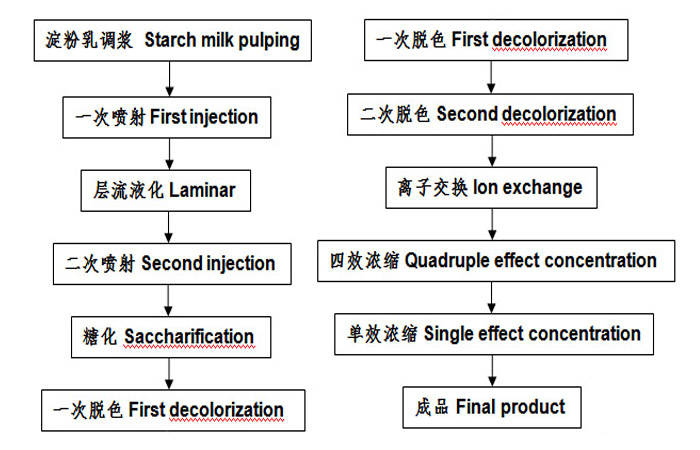

Step 1: Glucose fructose syrup mixing and liquefaction section:

Mixing the starch with clean water, then concentration to 18Be, adjust PH value to 5.6-6.0. then put the α-enzyme, deliver the liquid to jet cooker with steam heating temperature 100-108℃.

Step 2: Protein in starch liquid filtering process:

The starch liquid is delivery to plate frame filter press machine to remove the protein then the separated proteins can be washed, dried and crushed to packed into the warehouse changed to animal feed. This increase the add-value of your plant.

Step 3: Saccharification section:

This section use the saccharifying tank, adjust the glucose fructose liquid temperature to 60℃, PH value to 4.2-4.8, put saccharify enzyme, then keep 36-50 hours.

Step 4: First decoloring section:

Adding activated carbon to the liquid, this part cost time 0.5 ~ 1 hour, then send the liquid to plate frame filter press machine for decoloring to get bright and pure glucose fructose syrup, this time the transmittance of the solutions should more than 75%.

Step 5: First Ion exchange:

When the solutions temperature is decreased about 42℃, send to ion exchange column. The conductivity value of the final liquid is less than 20ppm.

Step 6: Pre-concentration section:

After ion exchange process, pre-concentration the glucose syrup liquid to 45Bx.

Step 7: Second decoloring:

Also use activated carbon to make decoloring for glucose syrup making, but this time the transmittance should be 95%. This time the gluctose fructose syrup get the pure degree requests.

Step 8: Second ion exchange:

This time should decrease the temperature to 30-35℃, then transfer to ion exchange system, the conductivity of the glucose syrup is more than 95%.

Step 9: Glucose fructose syrup evaporation process:

In this section, evaporator usually used three-effect type, high speed to make the syrup suit requests.

Step 10: Final glucose fructose syrup storage:

Suggest you select sida Company full stainless steel glucose fructose syrup storage tank, served for following packing and shippment.

Glucose fructose syrup production technology features:

1. No pollution water, our technology not produce waste water.

2. One set syrup making machine can produce three different syrup: fructose corn syrup, glucose syrup, and maltose syrup.