Liquid glucose syrup plant

Release Time:2020-07-14 10:37Author:sd888Source:未知

Any questions about the product can be communicated with us at any time!

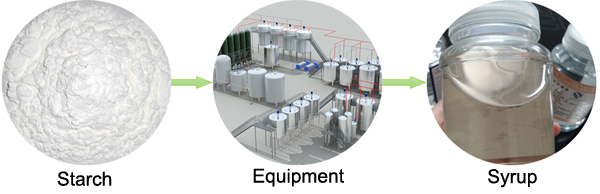

Liquid glucose plant

Liquid glucose plant production procedures are:starch mixing process,liquefaction process,protein-removing process,saccharification process,decolorization and decarburization process,ion exchange deionization process,evaporation process and filling an

Liquid glucose is the most important product in the starch processing industry. It is widely used in various foods such as candy, cakes, beverages, cold drinks, baking, canned food, jam, jelly, dairy products, etc. Our liquid glucose plant for sale is used to convert starch into glucose. As for starch used for glucose production in liquid glucose plant, corn starch is the best choice, potato starch and cassava starch can also be used for glucose making.

The process of making glucose from starch in liquid glucose plant is actually the process of converting starch polysaccharide into glucose monosaccharide. Making glucose from starch is finished by different liquid glucose plant for sale, procedures are as following: starch mixing process, liquefaction process, protein-removing process, saccharification process, decolorization and decarburization process, ion exchange deionization process, evaporation process and filling and packing process. Next is the details process description:

Protein-removing and saccharification process:

Before the saccharification process is proceed in liquid glucose plant for sale, protein in the dextrin has to be separated to make sure that we can get saccharification finished completely. Protein separation could be done by filter press machine, which can separate solid materials from liquid dextrin. Saccharification process is finished by specific enzyme in liquid glucose plant process. By adding saccharifying enzyme, we can get glucose and fructose. If fungal enzyme is applied, we can get liquid maltose. During the process, temperature and time should be controlled strictly. Usually it will take about 12-20 hours to finish saccharification.

Impurities-removing and glucose refining process of liquid glucose plant:

This part is divided into three process: decolorization, decarburization and ion exchange deionization process. To make liquid glucose colorless, activated carbon is added in the liquid glucose. Activated carbon has strong adsorption ability to organic impurities. And activated carbon is insoluble in water, and then we can use filter press machine in liquid glucose plant for sale to remove the activated carbon as well as organic impurities from the sugar solution. After the water-insoluble impurities and organic impurities in the sugar liquid are removed, there still contain many inorganic impurities dissolved in water, which exist in the form of cations and anions in water. Ion exchange column is used to remove these water-soluble inorganic impurities.

Evaporation and packing process:

After previous steps, impurities in the liquid glucose are mostly removed. The last step will use evaporator to remove excess water and get final glucose syrup in certain density. Three-effect evaporator is commonly used. After all process of liquid glucose plant for sale is finished, and we get required DE value and DS value glucose. Liquid glucose usually is filled and packed in barrel by hand or by packing machine if necessary. To make sure the liquid glucose can be stored for long time, we should take control of temperature and DS value of finished products.