Yuca processing machine

Release Time:2020-01-08 16:08Author:sd888Source:https://www.cndamachines.com/

Any questions about the product can be communicated with us at any time!

Yuca flour production process can be divided into several section: washing, grinding, desanding, dehydration, drying, packaging. Each section of the Yuca flour processing machine is connect to each other, the Yuca flour processing line can finished the entire production process automatically.

1. Yuca washing and peeling machine

Yuca flour are processed through a series of steps. Because the high impurity content will affect the quality of Yuca flour, we need to use the Yuca flour processing machine for peeling and washing to remove the Yuca surface soil and skin. Generally, the Yuca washing machine and Yuca peeling machine should be work together for getting high quality Yuca flour in Yuca flour processing plant.

2.Yuca grinding machine

The Yuca flour grinding process of Yuca flour processing machine is not same as Yuca starch grinding process. Adding as little water as possible during the Yuca grinding process. The crushed material is generally not filtered, to prevent loss of nutrients.

3. Yuca flour dehydration:

To getting dry Yuca flour, crushed Yuca slurry need dewatering first.The Yuca flour processing machine for dewatering has centrifugal dewater machine ( small-scale Yuca flour processing machine) and scraper centrifuge( medium or large capacity Yuca flour processing machine).The dewatering machine is used to reduce the water content of material and improve the drying efficiency and quality.

4.Yuca flour drying and packing:

After the previous step, we get the wet Yuca flour, it need to be dried by the Yuca flour drying machine. Yuca flour drying process is similar to Yuca starch drying, it need flash dryer. The hot air contact with wet Yuca flour and take away the water inside of wet Yuca flour quickly, After drying by Yuca flour processing machine, the dry Yuca flour will go through screening, the required fineness Yuca flour can be directly packaged, the Yuca flour below standard will be crushed again.

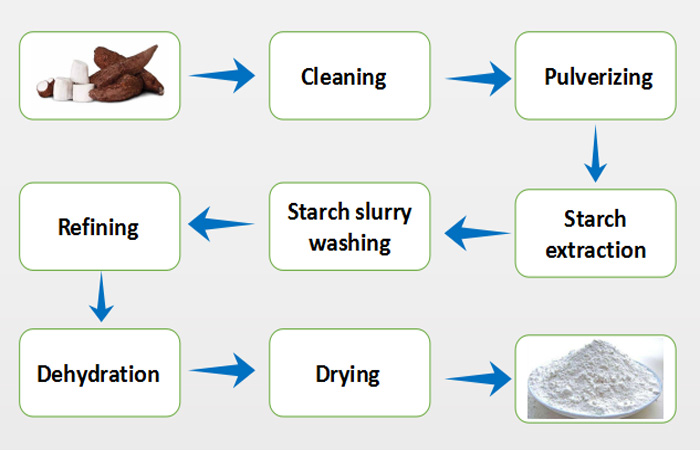

Yuca starch production line including raw material feeding, raw material cleaning, washing, starch extraction unit, starch and residue separation unit, de-sanding, starch refining system, vacuum dewatering unit, air drying system, starch screening and packaging. In the crushing section, SIDA rasping machine with national patent is used in grinding and screening sections, it smashes the material after multi-level filtering, multi-stage extrusion by a unique processing cycle. This Yuca starch production equipment has distinguishing features of low energy consumption, high starch extraction rate and good quality. The Germany Optibelt and Sweden bearing of this Yuca starch production equipment makes it sturdy and durable.

The whole line of Yuca starch production equipment includes: dry sieve, paddle washing machine, rasper, centrifuge sieve, fine fiber sieve, desander, hydrocyclone station, peeler centrifuge, flash dryer, Yuca starch screening machine and packing machine.

The main point of the article is the cleaning machine and washing machine in Yuca starch production equipment line.

In cleaning section, dry sieve is the mainly used Yuca starch production equipment. The fresh Yuca moves in the circular direction along the wall of the cylinder on the one hand, and linearly moves along the axis on the other hand, which lengthens the cleaning distance and the achieve a better cleaning effect.

The cleaning machine has the characteristics of high efficiency, low power consumption, low speed and smooth operation.

During the washing section, the paddle washing machine is multi-function and automatic feeding system. The Yuca starch production equipment for washing has good performance characteristics,the cleaning distance is lengthened and it can be partially peeled. The sediment, stone and skin residue are automatically discharged through the grid seam and the bottom drain of the shell. It has both washing and conveying functions, which reduces the height of manual feeding and makes feeding more convenient, then to reduce manual labor. Suitable for cleaning of block materials such as Yuca, banana.

This Yuca starch production equipment adopts the principle of countercurrent washing. The Yuca is consequential on the inlet into the rolling cage of the washing machine with the spiral strand to the outlet.

There are many advantages of Yuca starch production equipment:

First, the funnel type feeding reduces the difficulty of manually feeding, it makes the feeding way more convenient and easier.

Second, in the middle of the Yuca starch production equipment, the fresh Yuca moves in a circular motion along the wall of the cylinder. The comprehensive washing distance is greater than 20 meters. And can partially discharge sediment, stone and skin residue through the sewage outlet.

Third, this Yuca starch production equipment for washing with both the washing and conveying functions, there is no need to add a conveyor machine, which is highly efficient. (8 tons of Yuca can be washed per hour)