prices of cassava processing machines

Release Time:2020-01-11 10:26Author:sd888Source:https://www.cndamachines.com/

Any questions about the product can be communicated with us at any time!

Comprehensive technology-leading solutions

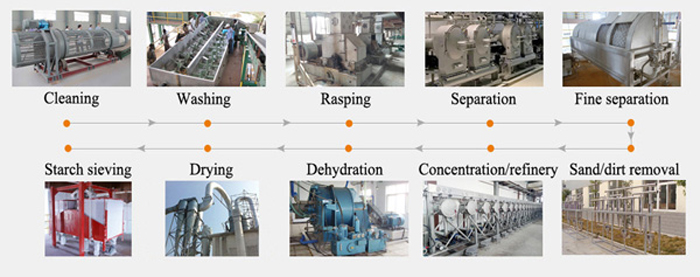

Cassava starch processing machine contains

Debris removal of cassava raw materials, cleaning machine

Cassava raw material crushing machine

Cassava starch extraction equipment

Cassava starch refining and concentrating machinery

Cassava starch dehydration machine

Cassava starch drying packaging machine

Cassava control system unit

Cassava flour processing machine contains

Debris removal of cassava raw materials, cleaning machine

Cassava raw peeling machine

Cassava raw material crushing machine

Cassava flour extraction equipment

Cassava flour compression system machinery

Cassava flour dehydration machine

Cassava flour drying packaging machine

Cassava control system unit

The entire cassava starch production system adopts a full set of European advanced mature process technology, combined with domestic equipment manufactured in accordance with European standards, can make the production system achieve excellent cost performance.

The entire equipment is fully enclosed, modular structure, compact layout and greatly reduces equipment installation time;

The core technology is more optimized on the basis of the original Europe;

The file grinder uses the only British COOPER bearing in the world that can provide heavy-duty bearings, which is to ensure that the file grinder can run stably under high loads;

The sand remover adopts a unique water separation system to ensure the discharge of sand and other impurities without running away powder;

The cyclone station has optimized various processes, completely replaced the butterfly separator, and has a better concentration and washing effect;

The air dryer dryer tube system reduces the steam consumption to nearly 30% of the current domestic level.

Reduced user operating costs.

The control system is stable and reliable, capable of producing high-quality products stably and continuously, and can provide various control systems from fully automatic to semi-automatic according to customer requirements;

The level of equipment manufacturing is close to Europe, and some even exceed the level of existing equipment in Europe.